Trim Puller Tool

- Ideal for removing baseboards and molding: The Zenith Trim Puller is designed specifically for safely removing baseboards, crown molding, door casings, decorative panel and even nailed or glued countertops

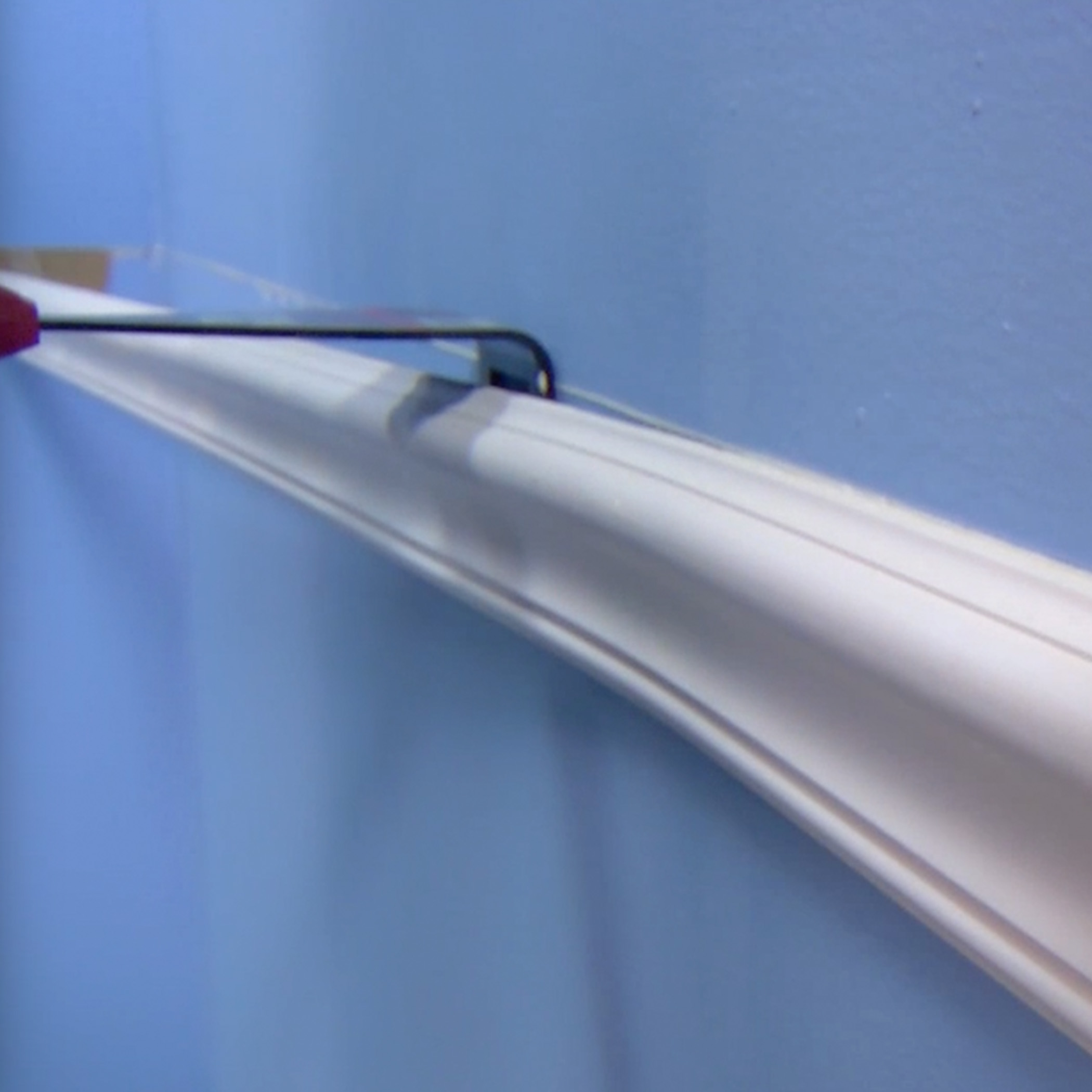

- Wedged center protects the wall and trim: The Trim Puller pry bar tool has a larger, flatter and wider contact area that features an integrated wedged center that provides increased removal efficiency and prevents damage to both the trim and wall

- Patented trim puller tool does all the work of a wrecking bar, trim removal tool, flat pry bar and claw and eliminates the need for a shim or small board spacer

- Comfort grip, shock-absorbing EDPM handle: This trim puller is capped off with an EDPM handle that feels comfortable in the hand while offering exceptional shock absorption

- Durable steel construction built to last: Made with durable high carbon, heat treated steel with a ground bevel on the edge which allows tool to easily be driven between trim and wall and also allows tool to be used as a shim for leveling cabinet bases

Product Description

The Zenith Trim Puller Removal Tool is a patented pry bar trim and baseboard removal tool that does all the work of a standard pry bar and claw without damage. The Trim Puller is a Pro-Tool Innovation Award winner designed specifically to safely and easily remove baseboards, molding, door casings and decorative panels without damage to the trim or to the wall and without the need for a shim or small board spacer. It has a larger, flatter and wider contact area than clumsy traditional tools and features an integrated wedged center that provides increased removal efficiency and prevents damage to both the trim and wall. Ideal for repair and remodel projects where care and precision are needed including cabinets, countertops, trim, flooring and much more. An impact absorbing EDPM rubber handle provides increased user comfort and its robust 48 Rockwell c heat treated steel construction provides durability. If demolition and trim removal for remodeling is your aim, well the Trim Puller will make fast work with your project. Save Time, Save Trim, Save Cash and Stop Damaging Walls. Switch to the Trim Puller today for all your remodeling and demolition projects.

3 reviews for Trim Puller Tool

- No Specifications available.

California residents prop 65 warning

This product can expose you to chemicals including Carbon Black, which is known to the State of California to cause cancer. For more information go to www.P65Warnings.ca.gov.

Este producto puede exponerte a sustancias químicas, incluso negro de humo, que el Estado de California reconoce como causante de cáncer. Para más información, visita www.P65Warnings.ca.gov.

Frequently Asked Questions

The Trim Puller is designed specifically for safely removing baseboards, molding, door casings, decorative panels, and even nailed or glued countertops.

Yes, the Trim Puller is designed for baseboard and trim removal. Its integrative wedge easily separates trim from drywall without damage.

Place the Trim Puller between the plank and wall. Wedge the Trim Puller slowly until fully separated. Repeat steps until entirely removed.

The Trim Puller’s Wedged center provides increased removal efficiency to prevent damage to both the trim and wall.

The Trim Puller is made of durable high carbon, heat treated steel, and a shock-absorbing EDPM handle.

Yes, the Trim Puller can be used to remove door casings, crown molding, baseboards, and wall trim.

The Trim Puller can be purchased on Amazon, the Home Depot, Lowes, Menards, and Do it Best.

Charleston Crafted –

YouTube Or Vimeo URL : https://www.instagram.com/charlestoncrafted/?hl=en

I’ve been using the Zenith Trim Puller for years on renovation projects in my home. It is the best tool I have found for removing all sorts of trim, including crown molding, baseboards, wainscoting and chair railings. The large surface provides a great strike area and allows...Read More

Dawson.DIY –

YouTube Or Vimeo URL : https://www.instagram.com/dawson.diy/?hl=en

I’ve used the Trim Puller for the past two years and absolutely love this tool! It makes it so easy to remove baseboards without damaging the drywall!

Steve Campise –

I truly love this tool! It is true to it’s claims it makes my job faster easier and cleaner! I enjoy using it every time!